Unibody frame repair, driven by technological advancements like CNC machinery, laser scanning, and 3D measurement systems, is revolutionizing auto industry standards for modern vehicle construction. These innovations ensure precise, efficient repairs, maintaining structural integrity and safety while integrating paint services seamlessly. As automotive designs evolve with lighter materials and advanced structures, unibody frame repair techniques adapt to meet these demands, offering enhanced efficiency, sustainability, cost savings, and improved customer satisfaction through superior aesthetic appeal.

Unibody frame repair is transforming the auto industry, offering more efficient and durable solutions for damaged vehicles. This article delves into the future of unibody frame repair, exploring current challenges and cutting-edge advancements. We analyze how technological innovations are revolutionizing the repair process, enhancing safety and reducing costs. Furthermore, we discuss the significant impact and benefits of improved techniques, highlighting their crucial role in shaping the industry’s landscape.

- Understanding Unibody Frame Repair: The Current Landscape and Challenges

- Advancements in Technology: Revolutionizing the Repair Process

- The Impact and Benefits of Improved Unibody Frame Repair Techniques

Understanding Unibody Frame Repair: The Current Landscape and Challenges

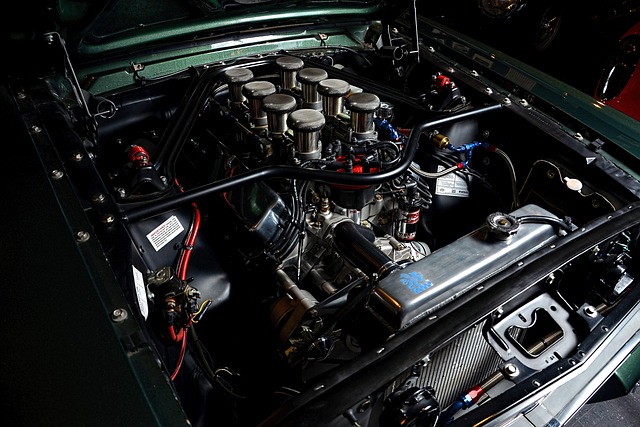

Unibody frame repair is a specialized process that involves repairing and restoring structural damage to modern vehicles with unibody construction. Unlike traditional frame straightening methods, unibody repair focuses on preserving the vehicle’s original factory-engineered design and integrity. The current landscape of unibody frame repair is characterized by advanced technologies such as computer numerical control (CNC) machinery, laser scanning, and 3D measurement systems that enable precise damage assessment and accurate repairs. These innovations have significantly improved the quality and efficiency of auto dent repair and car restoration processes, ensuring vehicles return to their pre-accident condition.

However, despite these advancements, unibody frame repair faces several challenges. The complexity of modern vehicle designs, with intricate structural components integrated into a unified frame, requires highly skilled technicians capable of handling delicate repairs without compromising structural integrity. Furthermore, the need for precise measurements and alignment ensures that every repair step is executed meticulously to avoid long-term performance issues or safety hazards. As the auto industry continues to evolve with lighter materials and advanced designs, unibody frame repair techniques will also need to adapt and advance to meet these new demands.

Advancements in Technology: Revolutionizing the Repair Process

The future of unibody frame repair in the auto industry is being reshaped by technological advancements that are revolutionizing the entire process. Modern cars, with their complex and intricate unibody structures, demand precision and efficiency in repairs to ensure structural integrity and safety. Technological innovations like laser welding, robotic precision tools, and advanced digital scanning systems have transformed how unibody frame repairs are conducted.

These cutting-edge technologies enable faster and more accurate repairs compared to traditional methods. Laser welding, for instance, offers unparalleled precision and strength, while robotic tools ensure consistent and meticulous work. Digital scanning systems accurately map the damaged area, providing detailed data for precise repairs. Furthermore, these advancements also facilitate better integration of car paint services, ensuring that both fender repair and vehicle paint repair are executed flawlessly, matching the original car’s aesthetics and structural soundness.

The Impact and Benefits of Improved Unibody Frame Repair Techniques

The evolution of unibody frame repair techniques is a game-changer for the auto industry, offering significant advantages in both efficiency and sustainability. By employing advanced technologies and innovative methods, professionals can now restore damaged vehicle structures to their original integrity, ensuring safer and more reliable cars. This transformation is particularly notable in the way it reduces the environmental impact associated with traditional frame repair processes.

Improved unibody frame repair techniques not only streamline the overall restoration process but also contribute to cost savings for both consumers and businesses. With faster turnaround times and precise results, car paint services and bumper repairs become more efficient, leading to reduced labor costs. Additionally, the ability to precisely match vehicle paint repair with the original factory finish enhances the aesthetic appeal of repaired vehicles, increasing customer satisfaction.

Unbody frame repair is evolving rapidly, driven by advancements in technology and a growing focus on efficiency and sustainability. As the auto industry progresses, adopting improved techniques for unibody frame repair will not only enhance vehicle structural integrity but also reduce repair times and environmental impact. This shift promises better outcomes for both manufacturers and consumers, paving the way for a more resilient and eco-friendly automotive future.